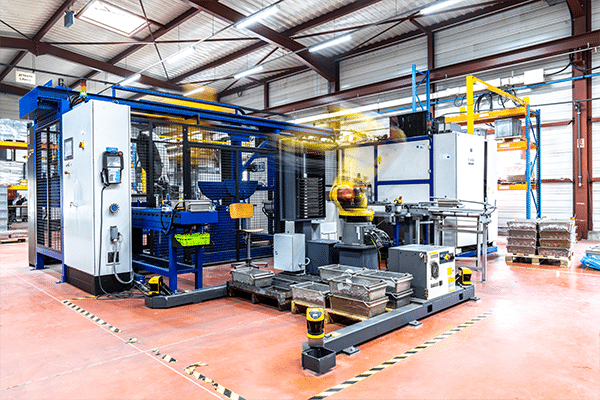

Our technical department determines the optimal manufacturing process by developing clamping and machining systems to ensure product quality (calculating deformations during machining, anticipating distortions after heat treatment, etc.).

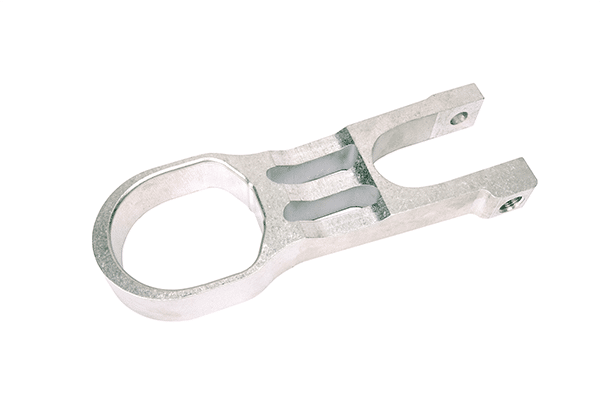

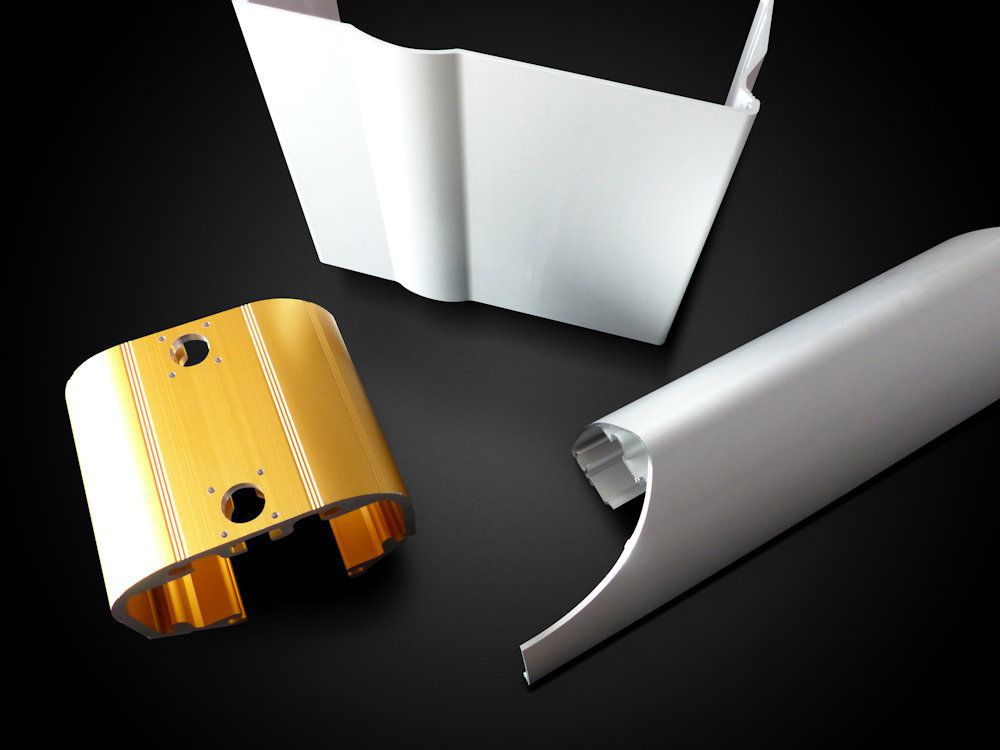

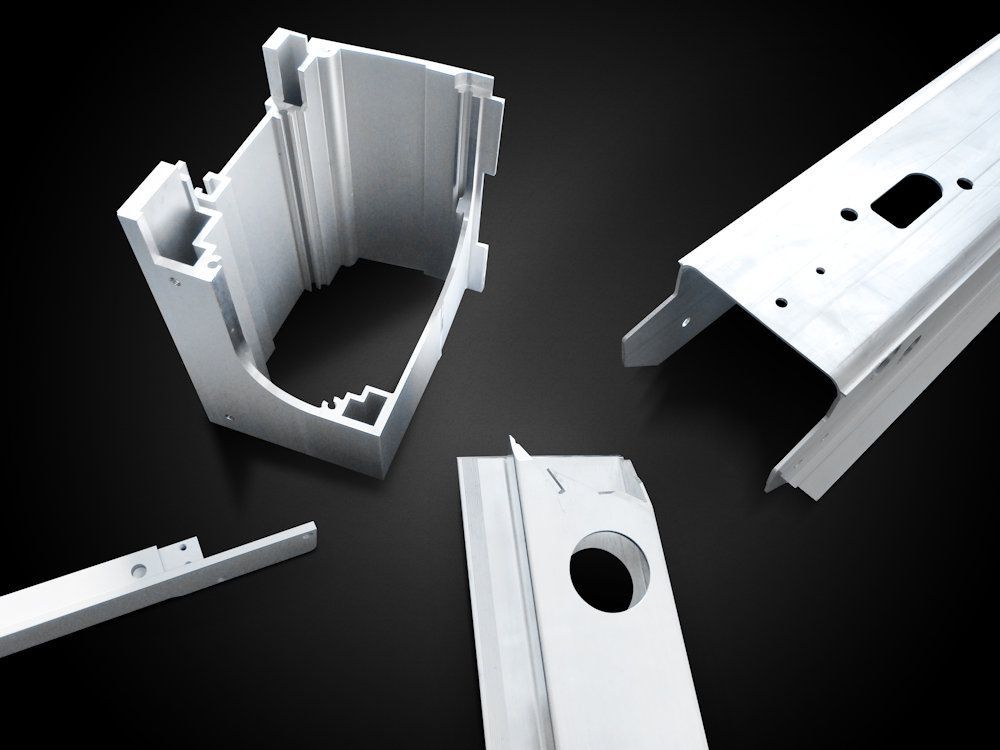

We produce precision machined components for the aerospace industry from extruded aluminum profiles.

This material offers weight savings (increased energy efficiency), mechanical strength (T4 or T6 heat treatment), durability, and recyclability.

Aluminum can be made from a 75% recycled composition to reduce its carbon footprint.

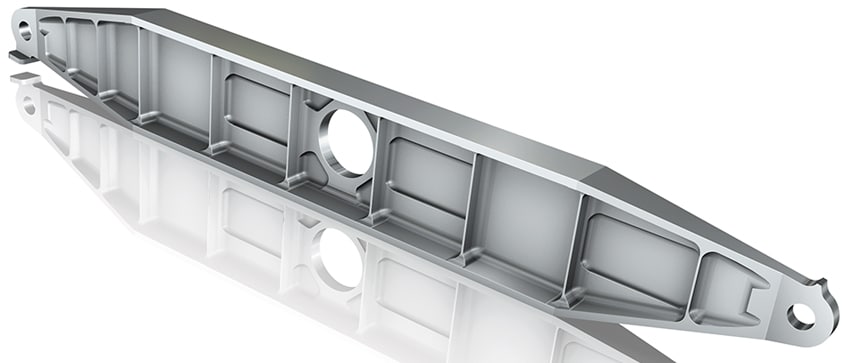

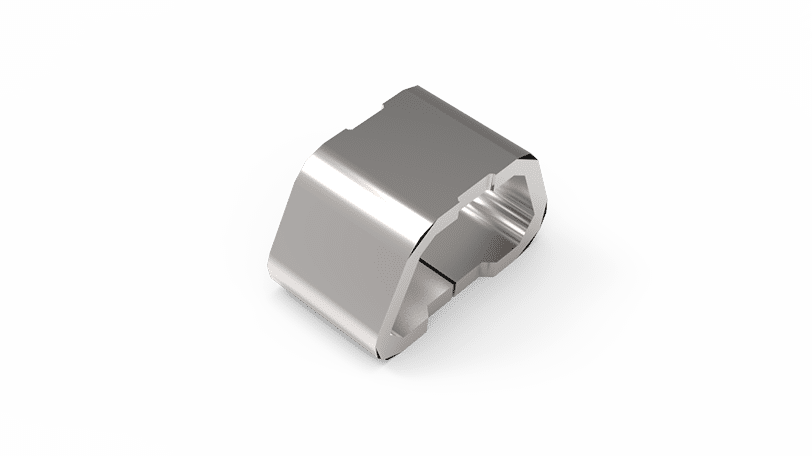

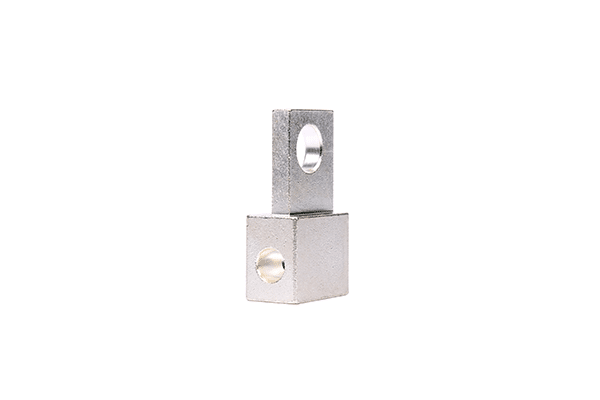

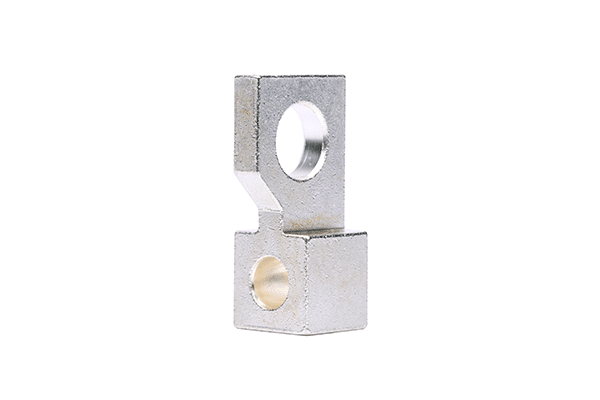

Precision components machined from profiles in steel, stainless steel, titanium and nickel alloys, are primarily used for fastening, interior equipment, and linking applications

Steel profiles can be used in structural connections where superior strength is critical.

Titanium profiles can be used for interior components such as seat structures and other elements where high strength and lightness are required.

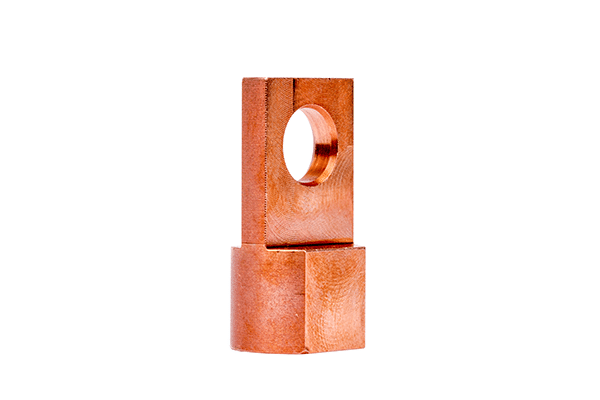

We produce precision components from copper alloys profiles, promoting electrical conductivity. These components are particularly used for low and high voltage connectors.

High and low voltage connectivity components out of copper profile with silver plating

We combine additional operations with machining to improve the quality of our products.

We perform in-house finishing by shot peening or mass finishing for deburring, polishing, and improving surface criteria (roughness and bearing capacity).

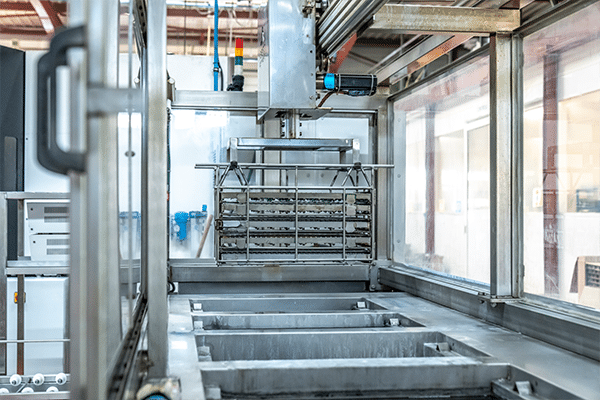

The cleanliness requirements of our products are guaranteed by a multi-tank, ultrasonic, detergent washing line and a robotized, modified alcohol washing line.

The cleanliness requirements of our products are guaranteed by a robotized, modified alcohol washing line.

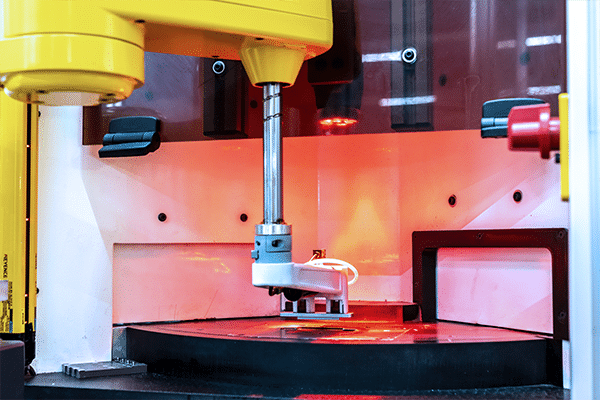

Unit traceability is carried out using automatic laser marking machines such as QR CODE or DATAMATRIX.